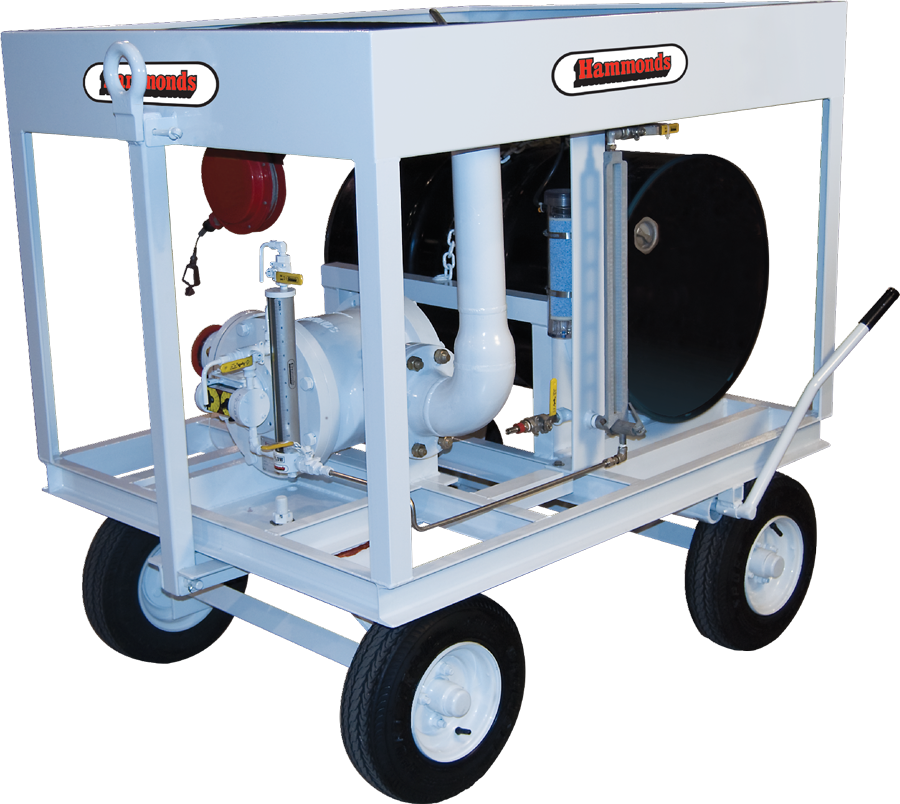

Designed specifically for high rate, large volume transfers, these systems handle typical airline fueling operations. Operation is automatic with nothing to turn on and off or adjust.

- Handles Ratios up to 2500 ppm

- Accurate additive dosage

- Thorough, complete blending

- Easy custom connections

- Inject up to 4 additives

SPECIFICATIONS

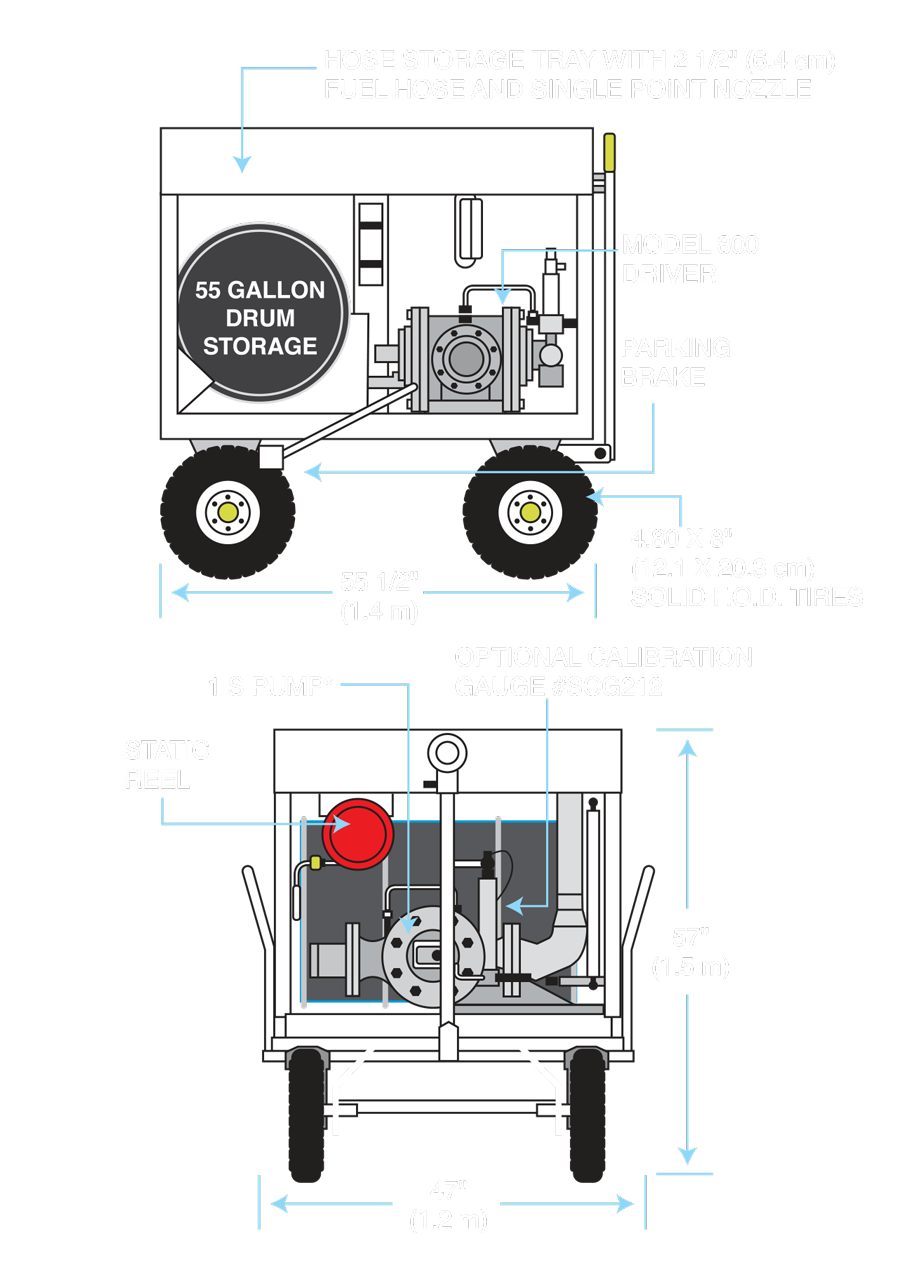

- Hammonds Model 800 fluid motor

- Hammonds 1S pump for ratios up to 400 ppm

- Number of additives: 1 standard, 2, 3, or 4 optional

- Product Inlet: Single point receptacle

- Product Outlet: Single point fueling nozzle

- Injection ratios: 0-4000 PPM depending upon application

- 75-700 GPM (284-2,649 l) continuous operation standard

- 50-750 GPM (189-2,838 l) intermittent operation

- Product temperature range: -40° - +250° F (-4.4° - +121.1° C)

- Maximum product line pressure: 100 PSI

- 55 gallon (208 l) drum rack with hold down

- Drum quantity level gauge

- HV Sight Flow Indicator with suction strainer

- Large capacity desiccant dryer

- Product hose: 15' x 2 1/2" aviation fueling hose

- Stainless steel flexible additive hose with quick disconnects

- Parking brake

- Static ground reel

- 4.80 x 8" (12 x 20 cm) F.O.D. tires

- Product viscosities: to 10,000 SSU

- Fuels, oils, additives, and liquid gases

CONSTRUCTION MATERIALS

- Hard anodized aluminum or carbon steel

- Metering pump: All wetted parts 300 series stainless steel

- Elastomers: Aflas, Viton and Teflon

- Mechanical Seal: Carbon on ceramic

- Overall dimensions: 47" W x 55.5” L x 57" H

- Weight: 1,000 lbs.