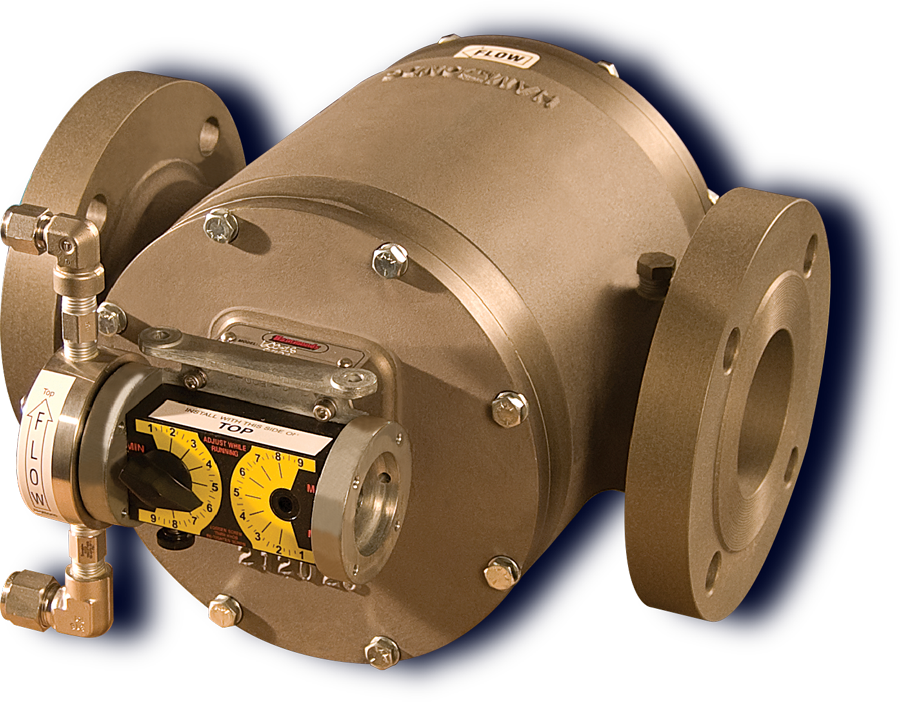

Our most popular system, The Model 600 injector offers single or multiple additive injection at flow rates typically found in aviation refuelers, hydrant systems, heating oil delivery trucks, dye injection and bulk receipt injection.

- Responds accurately to low flow rate changes

- No power or meter required

- Even and accurate blend even at low flow

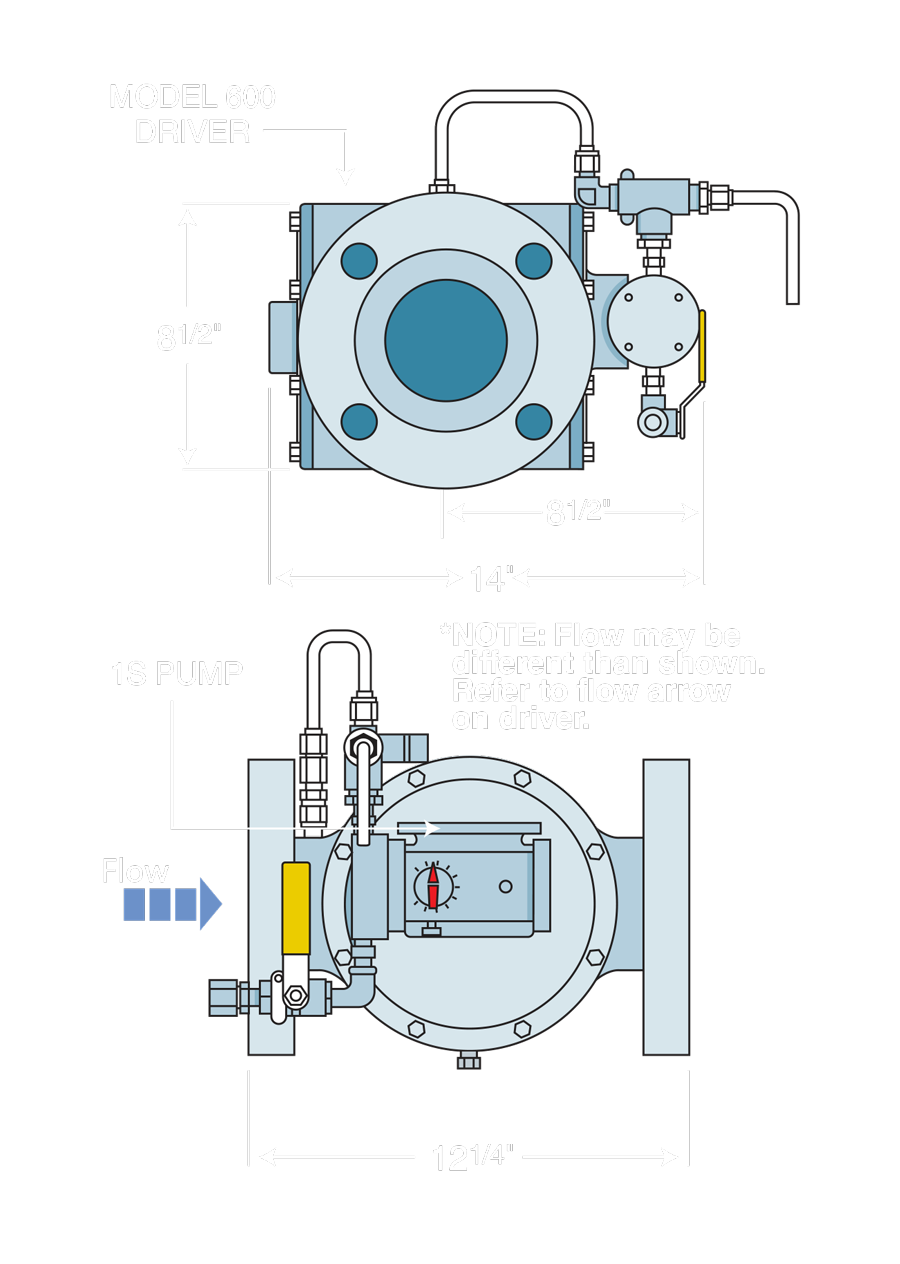

- 3” 150# ANSI connections

- Passive, automatic operation

SPECIFICATIONS

- Flooded suction required

- Number of Additives: 1 Standard, up to 4 optional

- 3" 150# connection standard (other connections available, consult factory for details)

- Injection Ratios: 0-4000 ppm depending upon application

- 20-250 gpm continuous operation

- Product Temperature Range: -40°F to +250°F (-40°C to +121°C)

- Maximum product line pressure: 150 psi. Higher pressures available with upgraded flanges installed

- Product Viscocities: up to 10,000 ssu

- Fuels, Oils, Additives and Liquid Gases

- Duty Cycle: Intermittent

CONSTRUCTION MATERIALS

- Aluminum casting; carbon steel fabrication optional

- Metering Pump: All wetted parts 300 series stainless steel

- Elastomers: Aflas, Viton, and Teflon; other elastomers available upon request

- Mechanical Seal: Carbon on Ceramic, optional Tungsten on Carbon

- Upgrade to Hammonds "Smart" System