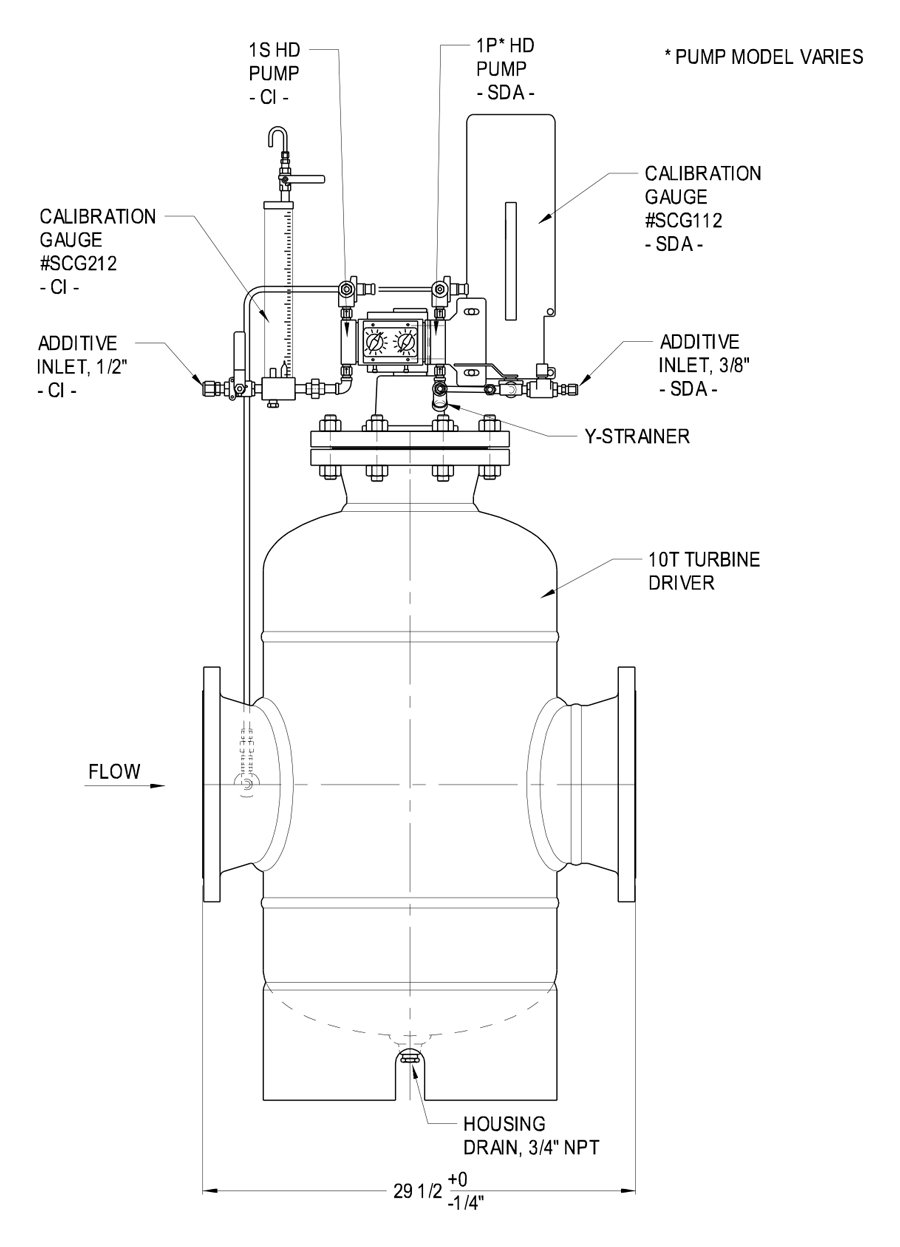

The 10T Series system offers single or multiple additive injection at flow rates typically found in fuel delivery terminals and transport trailer fill stands. The unique turbine-powered fluid motor responds precisely to changes in product volume even at lower product flow rates. Like all Hammonds injection systems, the 10T dispenses precise quantities of additive at a continuous rate, eliminating the “slugging” effect typically found in meter-pulsed injectors.

- Unique Fluid-powered Turbine injection

- Product meters or pulsars not required

- Even and accurate blend

SPECIFICATIONS

- Flooded suction required

- Number of Additives: 1 Standard; up to 4 optional

- 10" 150# connection standard (other connections available, consult factory for details)

- Injection Ratios: 0-4000 ppm depending upon application

- 700 - 3000 GPM continuous operation

- n/a intermittent operation

- Product Temperature Range: -40°F to +250°F (-40°C to +121°C)

- Maximum product line pressure: 150 psi. Higher pressures available with upgraded flanges installed

- Product Viscocities: up to 10,000 ssu

- Fuels, Oils, Additives and Liquid Gases

- Duty Cycle: Intermittent

CONSTRUCTION MATERIALS

- Carbon Steel Construction

- Metering Pump: All wetted parts 300 series stainless steel

- Elastomers: Aflas, Viton, and Teflon; other elastomers available upon request

- Mechanical Seal: Carbon on Ceramic, optional Tungsten on Carbon

- Upgrade to Hammonds "Smart" System