Vision Systems represent a new level of accuracy, dependability and ease of operation in additive injection. The systems are electronic and operate from any AC or DC current available on any vehicle or fixed installation. State-of-the-art, touch-screen controls make setting and operating the system easy, using menu-driven tasks to provide not only a perfect, on-spec blend of fuel and additive, but also a custom and retrievable data record relative to each fuel transaction.

- Audit trail from fueling events

- Accurate, automatic additive blending

- Real-time monitoring of injection

- Touch screen controls

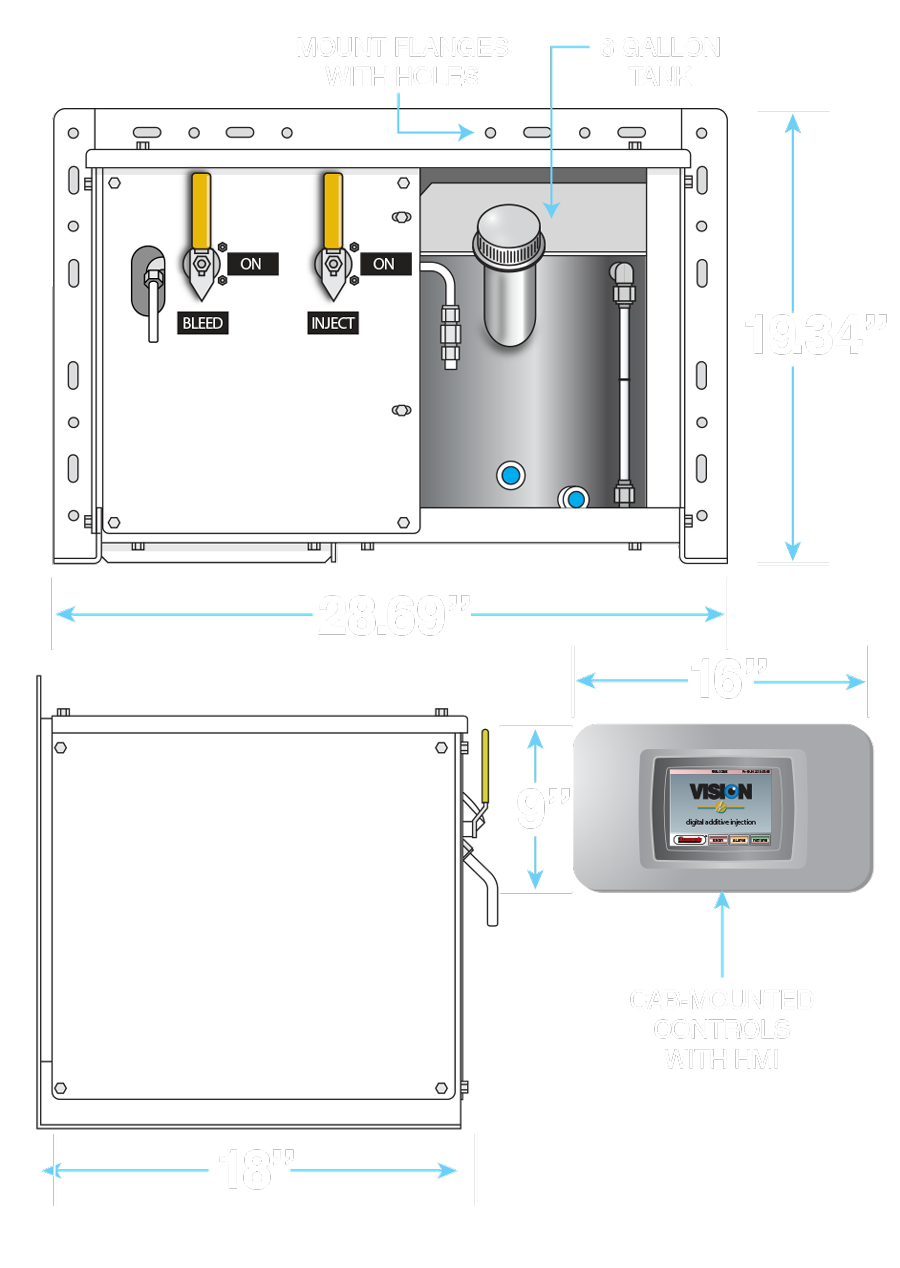

SPECIFICATIONS

- Solid-State Digital Processor in NEMA 12 enclosure

- Monitor pilot lights for operation

- Number of additives 1, 2, 3 or 4

- Fuel flow range: 0-800 GPM

- System operating pressure: 0-150 PSI

- Additive ratio: 30-1,500 PPM

- Standard operating temperature range: 32°-122°F

- Meter communication: High speed counter impulses per second (0-10kHz)

- Communicaton: Serial or discrete IO

- Standard PLC control relays: two (2) alarms, lights, signals

- Additive capacity: 6, 10, 15, 20 US gallons (6 gal standard)

- Additive tank material: 304 stainless

- Tank accessories: desiccant dryer, mechanical level gauge, remote level gauge sending unit for system monitoring

CONSTRUCTION MATERIALS

- Additive meter register with digital readout and totalizer

- 5, 10, or 20-gallon stainless-steel additive tank

- Multiple meter controls